It was 1959 when Glascraft made their first Innovation – a Chopper Spray System for the then developing composites industry. Since 1988 Glascraft UK has been known for Innovation and Avante Guard Solutions.

In Composites Production it is recommended to process most GRP Resins & Gel-Coats at an Optimal Temperature of 18°C-21°C (broad range 15°C to 25°C). Many UK Fibreglass workshops are not fully heated or insulated and materials are often processed at sub-optimal temperatures. An inline heater can significantly improve the consistency and cure time of fiberglass resin, especially in colder environments. By preheating the resin, it ensures better mixing and flow, leading to a more uniform application and a stronger final product. This is particularly beneficial when working with polyester resin, which can be sensitive to temperature fluctuations.

Benefits include Improved Cure Time & Consistency; Lower Pressure Pumps; Reduced Emissions; Enhanced Mixing & Flow; Reduced Waste; Optimised Process; Speed & Quality. Overall, an inline heater offers a practical solution for maintaining resin quality and optimizing the composites process, particularly in situations where temperature control is crucial.

Inline Heaters mean that the whole IBC or 200 litre drum do not need to be brought up to the correct temperature (which is timely – a drum can take a day to warm up and an IBC can take 3 days). Inline Heaters give “Instant Heat” for the material flowing towards the spray gun from the cold drum or IBC.

Problem #1 : Historically, Inline Heaters have had a major issue. Resins & Gel-coats can be baked solid if the heater is left at a high temperature with no material flow. When this happens it either requires a whole new heater or extensive repair/component replacement which is very expensive.

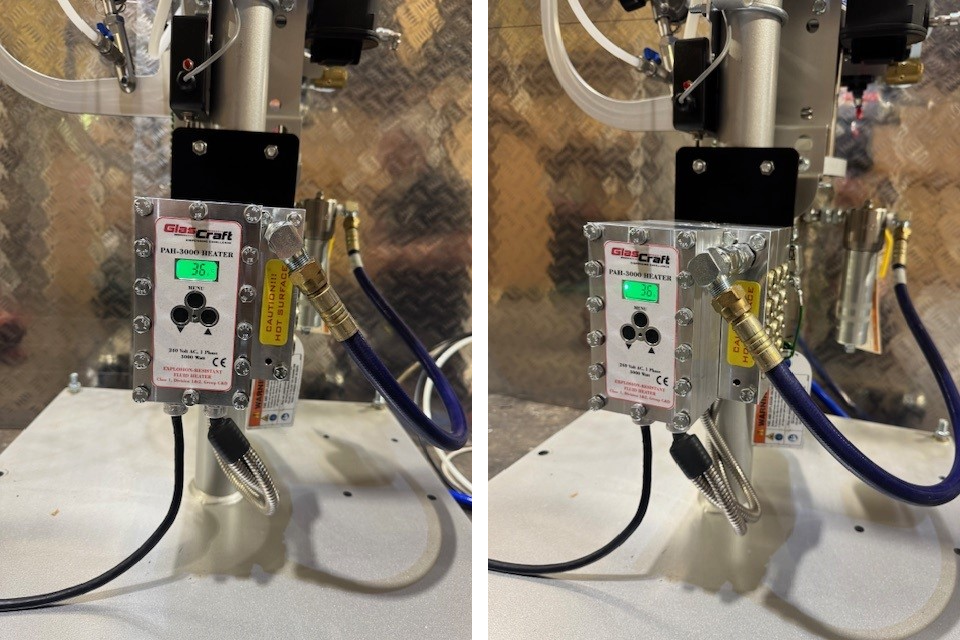

Solution #1 : The Explosion Proof Repairable Inline Heater is designed to be repaired in-house! The innovative design gives efficient heating of materials but also allows for “drilling out” of the Fluid Passageways in-house by your own maintenance staff. This negates the need to call out an engineer or send the heater away for repair. This solution limits downtime and expense. Keeping you running at optimal performance with minimal downtime and minimal cost.

Methodology: Remove Cleaning Access Blanking Plugs and drill out diagonal fluid passageways, replace any O-Rings that look swollen or damaged & reassemble. The only repair cost will be a handful of O-Rings. NOTE: Glascraft Supply a “Cleaning Drill & O-Ring Kit” to facilitate your own in-house repair.

Problem #2 : Inline Heaters fitted to Chopper Spray, Resin Wet-Out or Gel-Coat Spray systems heat material, however the material hose from the heater to the spray gun is cold. Initially you get cold material out of the gun giving issues of narrow fan pattern, slow cure etc. This leads to Operators “spraying to waste” until the fan pattern comes good. This has a triple cost: 1) waste of Time, 2) Waste of Material & 3) cost of waste disposal.

Solution #2 : Glascraft has a Unique “Heat-To-Gun” Recirculation System for the Spray Hose Assembly bringing Warm Material up to the Gun. Coupled with our “Switched” Catalyst Flow Alarm this gives Zero Waste & Peace of Mind.

The Repairable Inline Heater & Heat-To-Gun Hose Recirculation is available on all New Graco RS Spray Systems and can be retro-fitted to any make of Composite Dispense System. Please contact us for further details: ENQUIRE NOW

PS If your Fibreglass Factory is Not insulated why not enquire regarding our Spray Foam Insulation Products. This will significantly reduce heating costs and promote heat retention.

Download: Repairable inline Heater